Because of their higher iron content, ferrous metals are often stronger and more resilient than non-ferrous metals. This inherent strength makes them perfect for heavy-duty applications including construction, infrastructure, and machinery. When comparing ferrous vs non-ferrous metals, ferrous metals perform better in harsh conditions because they are more resilient to wear, stress, and impact. They are necessary for tasks that call for sturdy and dependable materials because of their durability and strength.

Here are five ways ferrous metals are more robust and long-lasting than non-ferrous metals:

Higher tensile strength

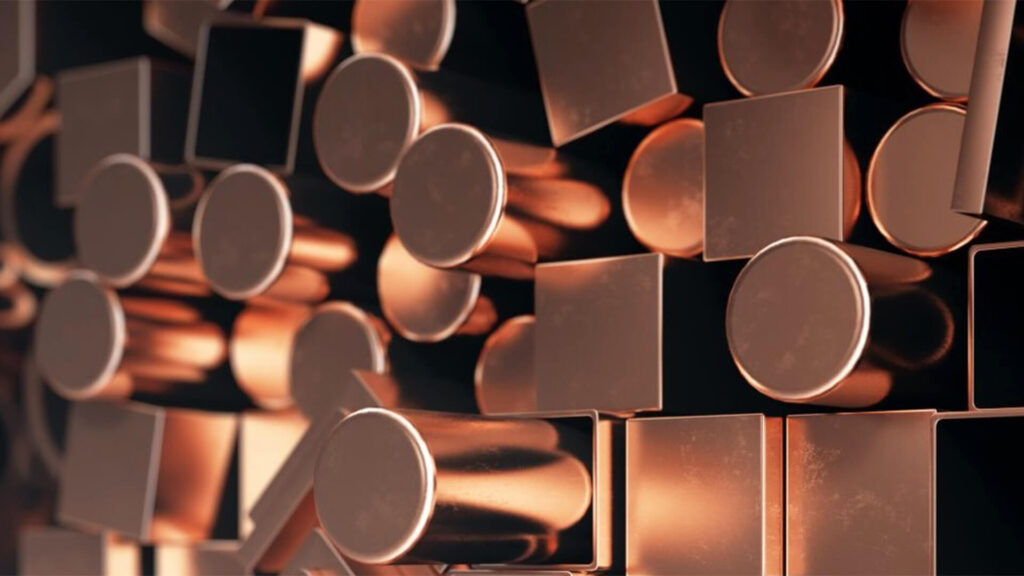

Comparing non-ferrous metals like copper or aluminum to ferrous metals like steel and iron, the former have a greater tensile strength. This makes them more appropriate for heavy-duty uses, such as the construction of equipment, bridges, and buildings, where robust materials are needed to support large weights.

Greater wear resistance

Because of their hardness, ferrous metals are more resilient to deterioration. They are more suited for industrial applications since they can withstand repetitive stress and strain. Despite being lightweight and adaptable, non-ferrous metals may deteriorate more quickly in harsh settings.

Heat resistance

Ferrous metals are more resilient to high temperatures and have higher melting points. As a result, they are more resilient in hot settings like furnaces and engines. In such circumstances, non-ferrous metals such as aluminum might weaken or distort.

Impact resistance

Ferrous metals are strong and can absorb and endure strong impacts without shattering or changing shape. This is especially significant in the manufacturing and construction industries, where impact resistance is essential.

Longer lifespan

In applications where strength is important, ferrous metals often have a longer lifespan. Because of their flexibility and resistance to corrosion, non-ferrous metals are beneficial, but ferrous metals are more durable in settings that need for sturdy materials.

To sum up

Ferrous metals are the favored option for many heavy-duty applications because they are more robust and long-lasting than non-ferrous metals.